Fill out the form below and someone from our team will get in touch with you to help with any question you may have

Some of Our Services

Our range of services caters to the diverse needs of electronics manufacturers, ensuring top-notch quality in every project. Here is a list of some of our PCB plating services.

Industries We Serve

-

78,281

orders Processed

-

2,425,442

ITEMS FINISHED

-

253

companies

-

23

years IN BUSINESS

Why Work With AFI

Here are the reasons to partner with AFI as your metal finishing company for all your electronic component plating;

- We offer metal plating and surface finishing for high-reliability electronics.

- Our work is found in mission-critical systems in medical, military, and other industries nationwide.

- We finish many of our jobs within one day, with the option of completing plating jobs on the same day for customers with urgent needs.

- We help our customers develop robust and cost-effective solutions by advising and improving our customers’ existing designs as products evolve.

- We will also help our customers troubleshoot defects and investigate failures.

- AFI is also an IPC member, and AS9100D, ISO 9001:2015, and ITAR registered.

Precision & Quality

Strict quality checks ensure flawless results

Custom Finishing

Tailored solutions for diverse industries

Advanced Technology

Equipped for complex, large-scale projects

Fast Turnaround

Quick completion without sacrificing quality

Eco-Friendly

Sustainable, environmentally friendly practices

Certified Excellence

Industry-certified processes ensure compliance with the highest standards

Technical Expertise

Expertise in surface preparation, coating adhesion, and corrosion resistance ensures long-lasting, high-performance finishes

Who We Work With

As a metal finishing company, we collaborate with US and Canadian electronics manufacturers, as well as engineers, purchasing agents, and quality control personnel seeking ENIG finishing and metal plating services for printed circuit boards and electronic components.

PCB Plating Processes

Quotation For Surface Finishing PCBs and Electronic Components

Our plating process at Alternate Finishing, Inc. begins with reviewing your requirements to understand the size and shape of the items to be worked on, the finish type, and the tolerances.

The price is calculated based on factors like materials, complexity, layer count, type of finish, and lead time. Some clients may have specific requests for expedited processing or custom finishes.

Order Preparation

Once your order is received, a detailed job tracking record is created to organize and guide the operators through the processing steps. This job tracking information provides all the necessary details for handling the parts according to your specifications, ensuring that every step of the plating process aligns with your original requirements.

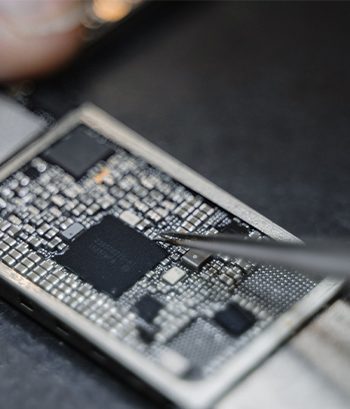

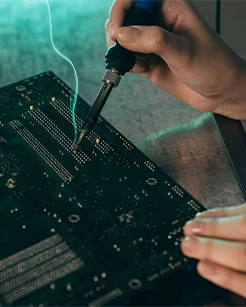

Preparation

The PCB panels or parts are cleaned and prepared to remove contaminants and oxidation that could interfere with adhesion during the metal finishing process. Any areas that are not to be plated can be masked at this time as well.

The items will next be put on fixtures or racks to facilitate processing more than one at a time.

Coating Application

Depending on the final required surface finish for the PCBs or other components, the parts are processed through a series of chemical solutions with rinses between them to deposit the metal layers requested by our customer.

At this point in the plating process, the parts are rinsed in deionized water and dried.

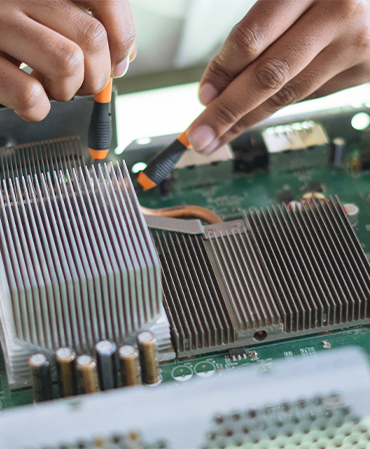

Testing and Inspection

Finishes are checked for uniformity, thickness, and adhesion to ensure consistent results and adherence to the requirements.

Final Inspection and Packaging

Items are checked for cleanliness as they are being packaged. Parts are individually packaged, often with anti-static and moisture-resistant materials to prevent damage during shipping.

Documentation and Labeling

Packaging for shipment with the necessary documentation, such as quality certifications and any handling instructions is the next step

Shipping or Pickup

The final step in our plating process is delivery: either through shipping or pick up. The logistics are tailored to your requirements for speed and destination

About Us

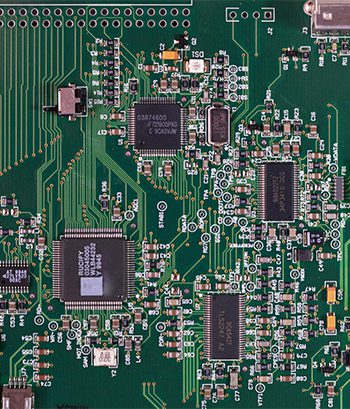

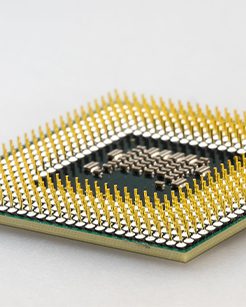

Alternate Finishing, Inc. (AFI) is a New England-based metal finishing company specializing in plating services like selective plating for electronic components and advanced metal finishing for PCBs to enhance the performance and durability of PCBs and electronic components.

With cutting-edge technology and a commitment to excellence, we offer various services, including electroless nickel immersion gold (ENIG plating process), nickel gold plating for electronics, nickel plating, copper plating, and immersion silver plating for circuit boards.

AFI is your dedicated partner for reliable solutions, optimizing solderability, improving corrosion resistance, and ensuring top-notch electrical conductivity in both cost-effective and premium finishes for high-reliability applications.

Schedule a consultation to explore the ENIG finishing and metal plating services AFI can give you.