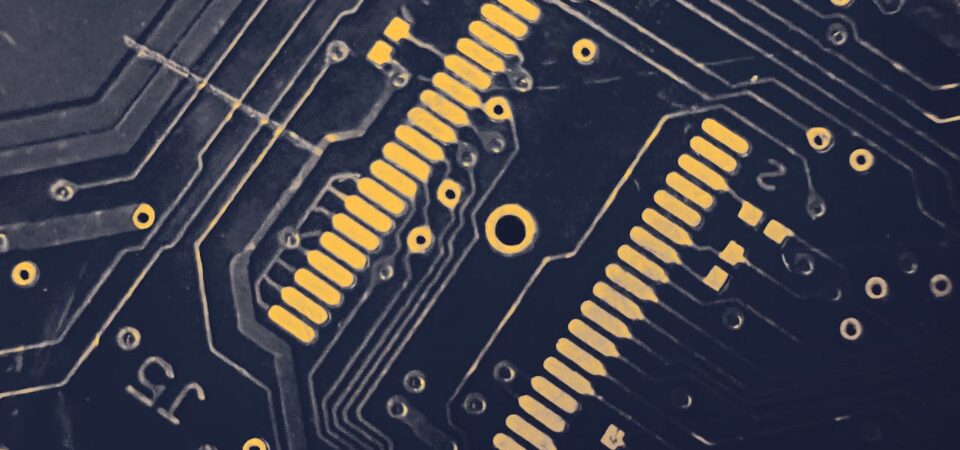

Gold has excellent electrical conductivity properties. It is also very resistant to corrosion and oxidation even in harsh environments. These and many other properties make it the ideal PCB manufacturing and assembly plating solution.

Electroless gold plating, in particular, uses a chemical reaction to deposit a layer of gold onto the substrate. This approach is not just different from the electroplating methods. It provides several unique advantages to PCBs and other electronic components which we will now discuss here.

The Advantages

Uniform Deposition

Uniform deposition does so much for a plated component. From reducing manufacturing defects and material wastage to ensuring reliable electrical performance and better thermal management, this consistent plating improves both the functional and aesthetic appeal of components.

When it comes to this method, in particular, even complex geometries and through holes are guaranteed a uniform coating.

Furthermore, with this uniform deposition, the smoother surface finish leads to reliable connections in PCB manufacturing and assembly.

Enhanced Solderability

We have already discussed gold’s strong resistance to oxidation and corrosion. Because of this, the solderability of the PCB pads is maintained over extended periods. More so, the corrosion resistance of electroless gold plating also keeps the pads solderable after prolonged storage or exposure to harsh environments.

The gold surface also provides great wetting properties for the solder. These properties lead to strong and reliable solder joints. If you are working with surface-mount technology components, the importance of this property cannot be overstated because, in such components, a good solder joint formation is critical for electrical and mechanical stability.

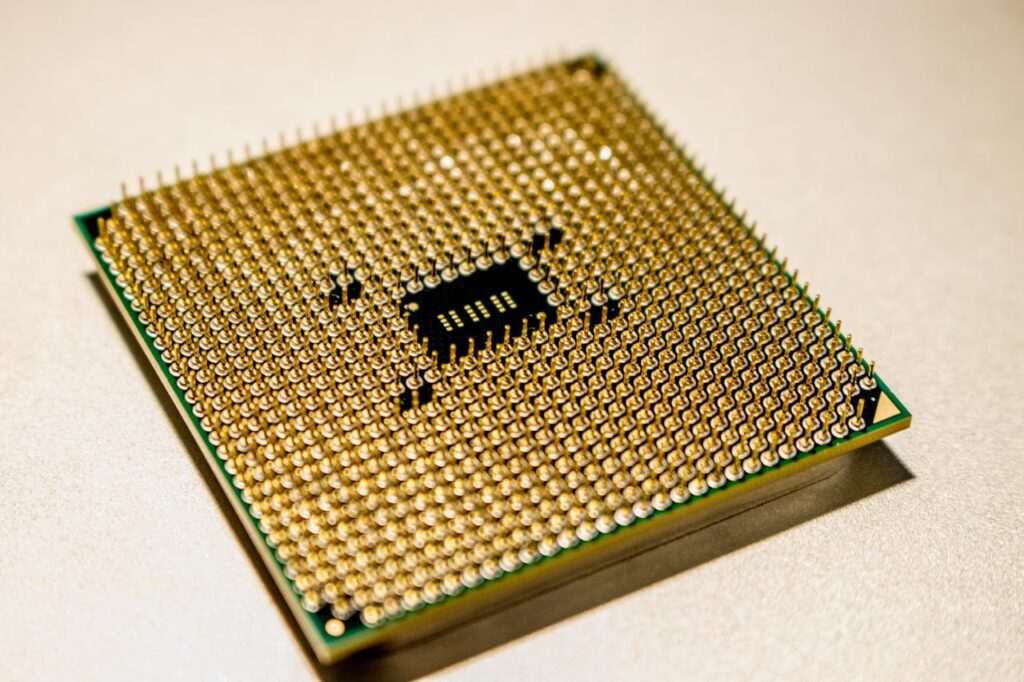

Improved Electrical Performance

Gold has low electrical resistivity. In PCB manufacturing and assembly, this is useful because it minimizes contact resistance and improves the overall electrical performance of the PCB. You’ll find this to be a great advantage for high-frequency and high-speed circuits that require low resistance and minimal signal loss.

The electrical performance is also improved because gold-plated contact points are stable and reliable which is ideal for connectors, edge contacts, and other critical contact areas in PCBs to guarantee consistent performance over time.

Compatibility With Fine Pitch Components

Electroless gold plating supports fine pitch components and fine line technology as we have already mentioned earlier. This is possible because of its uniform and thin coating capabilities.

Why is this important?

It is important in modern electronics, where miniaturization and high component density are prevalent.

In PCB manufacturing and assembly, the gold surface is also great for wire bonding, which is a process used to connect the integrated circuits to the PCB. The strong bondability of gold ensures reliable connections in advanced semiconductor packaging technologies.

Cost-Effectiveness

We cannot fail to mention the cost savings of this process. It’s true that gold plating can be quite expensive initially but you save more due to the improved solderability and reliability that the process gives you because it reduces the likelihood of assembly defects and rework.

Furthermore, gold-plated PCBs have an extended shelf life, so you will reduce waste and inventory management costs.

Metal Plating With Alternate Finishing, Inc.

At Alternate Finishing, Inc., we provide metal plating services to customers across the USA and Canada. This includes electroless gold plating for the PCB manufacturing and assembly industry.

We have a wide range of plating solutions too and as an IPC member and AS9100D, ISO 9001:2015, and ITAR registered, we ensure that all our plating jobs are reliable so we always deliver as promised.

We also have a quick turnaround on these jobs and some can even be done on the same day. Therefore, if you are considering outsourcing your PCB metal plating services, look no further. Simply call us for a quote.