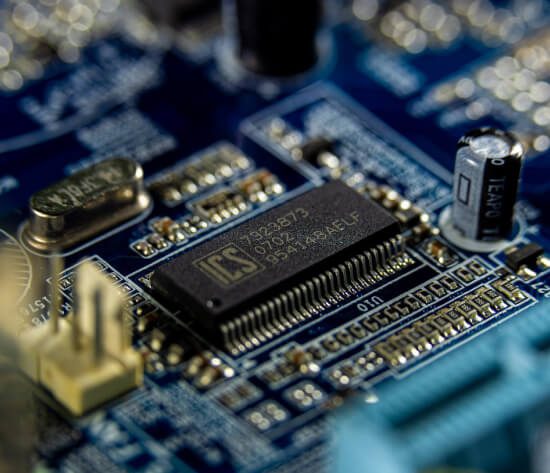

Overview of PCBs in Medical Applications

PCBs in modern medical devices provide the necessary electrical connections to support complex functionalities, like imaging and real-time data transmission. Reliable PCBs in healthcare prevent critical consequences that could result from device failure. For this reason, medical-grade PCB design prioritizes circuits that meet strict performance and safety standards.

PCBs are used in diagnostic equipment and several other medical technologies with varying levels of complexity. As technology advances, engineers now design high-density PCB layouts for complex medical electronics, enabling more compact and efficient medical devices.

Compliance and Certification Requirements for Medical-Grade PCBs

The manufacturers for these PCBs must adhere to key compliance and certification requirements to ensure device safety for patients and proper functionality. Here are some of the compliance and certification requirements.

ISO 13485

ISO 134585 is an internationally recognized standard that specifies the requirements for a comprehensive quality management system for medical device manufacturing. Compliance with this certification demonstrates a company’s ability to design and manufacture medical devices that consistently meet regulatory requirements and customer expectations and covers:

- Risk management procedures throughout the product life cycle

- Process validation for medical PCB manufacturing

- Traceability of materials and components

- Regulatory documentation requirements

The ISO 13485 certification is often a prerequisite for manufacturers aiming to distribute their medical devices in major markets like the US and Europe.

IEC 60601-1

This standard ensures that electronic medical devices meet safety benchmarks. It is meant to protect patients and operators from electrical hazards. Compliance with this standard is crucial for PCBs used in:

- Life-supporting devices such as ventilators and defibrillators

- Patient monitoring systems

- Diagnostic imaging equipment

This standard has some important safety considerations too. These are:

- Electrical Safety: Preventing shocks, leakage currents, and insulation failures

- Mechanical Safety: The medical PCBs’ durability and resistance to physical stress

- Electromagnetic compatibility: Ensuring the device does not interfere with or is not affected by external electronic systems.

IPC Standards

The IPC (Institute for Printed Circuits) develops industry-wide standards that define quality and performance benchmarks for PCBs. Here are some of the most relevant IPC standards for medical applications:

- IPC-A-610: This standard outlines the acceptability criteria for electronic assemblies, ensuring that solder joints, component placement, and assembly processes meet high reliability and durability standards.

- IPC-6012: Specifies the qualification and performance requirements for rigid PCBs, ensuring they can withstand environmental and operational stresses commonly found in medical applications.

- IPC-2221: Provides general design standards for printed circuit boards, including medical PCBs, like material selection, layout considerations, and manufacturability guidelines.

- IPC-4556: Covers Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG), an advanced plating method offering improved reliability for fine-pitch components in medical PCBs.

- IPC-4552: Specifies the performance requirements for ENIG plating, ensuring proper thickness, adhesion, and corrosion resistance.

In addition to the industry standards above, electronic medical devices, including PCBs must comply with regulatory frameworks like the FDA (U.S. Food and Drug Administration) 21 CFR Part 820 that covers quality system regulations for medical device manufacturers, ensuring proper design controls, validation, and documentation.

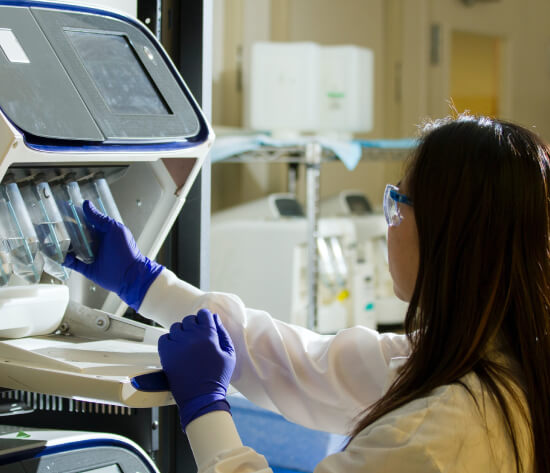

Common Medical Device Applications For PCBs

- Diagnostic Devices: PCBs are used in medical imaging systems like MRI, CT scanners, and ultrasound equipment to accurately process data, including image clarity, so as to aid in precise diagnostics.

- Monitoring Devices: Devices like heart rate monitors and blood pressure monitors rely on PCBs for accurate readings.

- Therapeutic Equipment: Devices like infusion pumps, which deliver precise amounts of fluids to patients, depend on PCBs to function reliably and accurately. This precision in PCB design helps these devices to effectively and safely administer treatments.

- Implantable Medical Devices: From pacemakers and neurostimulators, to implantable cardiac defibrillators and cochlear implants, all these implantable devices use flex medical PCBs due to their flexibility and reliability. The design of these PCBs ensures that they can withstand the physiological conditions within the human body while maintaining functionality.

The compliance and safety requirements for these PCBs and electronic medical devices also extend to plating to ensure reliability, conductivity, and longevity while meeting the strict industry standards for corrosion resistance and biocompatibility.

In the plating requirements, regulations like RoHS and REACH restrict hazardous substances and harmful chemicals to maintain material safety in medical devices. The common plating methods that are acceptable include Electroless Nickel Immersion Gold for corrosion and stability, electrolytic gold for high-frequency and implant applications, and silver or palladium for enhanced electrical performance and antimicrobial properties.

Medical PCB Plating With Alternate Finishing, Inc.

Alternate Finishing, Inc. (AFI) provides cutting-edge surface treatments for medical electronics. Our services on electronic medical devices include

- Medical device circuit board plating

- Healthcare electronics surface finishing

- Electroplating solutions for medical electronics

- Biocompatible PCB coatings

- Advanced surface treatment for healthcare PCBs

- Precision metal finishes for medical devices

- Custom plating services for healthcare electronics

- Electroless nickel plating for medical PCBs

- Gold plating for medical PCBs

- Biomedical electronics plating solutions

Work With Us

Alternate Finishing, Inc. excels in providing cutting-edge medical PCB plating services, guaranteeing precision, customization, advanced materials, regulatory compliance, and environmental responsibility.

Trusted by healthcare professionals, we ensure that PCBs for healthcare devices meet top standards for performance and reliability, supporting advancements that save lives and enhance patient outcomes.

If you are looking for reliable PCB plating services for your medical equipment, contact us for a free quote.