Elevating Electronics in Aerospace, Semiconductors, and Automotive with High-Tech Plating

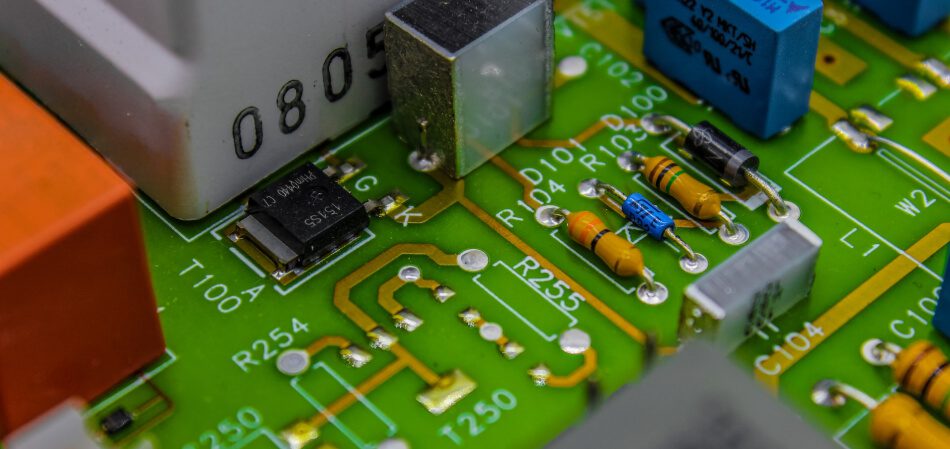

Metal plating is a surface modification technique that involves depositing a layer of metal onto a material. This process aims to enhance the characteristics of the substrate such as corrosion resistance, conductivity and aesthetics.

It finds applications in industries like aerospace for lightweight and corrosion-resistant materials, semiconductors for circuitry and connectivity through high-tech metal finishing and automotive for visually appealing and durable vehicle parts.

High-Tech Plating Services Offered By Alternate Finishing, Inc.

- Consultation and technical support

- Surface preparation

- ENIG plating

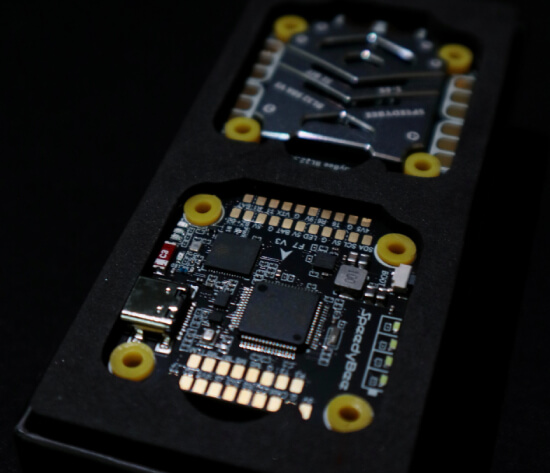

- Selective ENIG plating for high-tech PCBs

- Custom metal finishing services solutions

- Quick turnaround services

Quick Turnaround Plating With AFI

At AFI we proudly serve customers throughout the United States and Canada by providing high-tech metal finishing services for their PCBs and electronic components.

When you entrust us with a project we typically aim to complete and deliver the products in less than a week. Many jobs are completed the day after we receive the parts. For urgent tech plating needs we can often finish the job on the same day that we receive it. Call us for a quote.

The Unique Challenges of the Aerospace and Defense Industry

The aerospace and defense industries have strict requirements for materials and components, prioritizing high precision, safety standards, and rigorous performance expectations. Companies in these sectors must meet various challenges and requirements to ensure the reliability and safety of their products. Here are some of the primary challenges and requirements.

Strict Regulatory and Certification Standards

Aerospace and defense products, including electronics, undergo extensive regulatory oversight from agencies like the Federal Aviation Administration (FAA) and the Department of Defense (DoD).

The regulations often mandate compliance with specific material, design, and testing requirements to guarantee the safety and reliability of the components. Consequently, the high-tech metal finishing services we provide comply with applicable standards and regulations.

High-Performance Durability Requirements

Electronic and machine components must also be able to endure extreme conditions such as high temperatures, vibrations, radiation, and chemical exposure. The materials and coatings used must meet specific strength, corrosion resistance, and heat tolerance standards. These objectives are inherent in the high-tech plating.services that we offer.

Innovation and Technological Advancements

AFI is ready to adapt with the innovation of newer and safer technologies including advances in material science, such as lighter and stronger composites to achieve more efficient and capable defense systems.

Cost Control and Efficiency

While safety and performance are the top priorities, aerospace and defense companies must also focus on cost control because development cycles can be long and material costs high. We take a consultative approach with our clients to establish a balance between keeping costs low while having components that meet the highest standards.

AFI’s High-Tech Metal Finishing Solutions in Meeting Aerospace and Defense Demands

At Alternate Finishing, Inc., we provide critical hi-tech plating for PCBs and other electronic components used in aerospace and defense applications. Here is how our solutions contribute to addressing the challenges in these sectors.

- Precision and High-Quality Finishing: We use methods like electroless nickel plating, ENIG, silver plating, and more to address the concerns of durability, resistance to ware, and corrosion resistance. These finishes improve the performance and longevity of the electric components that are subjected to harsh operating conditions.

- Compliance with Aerospace and Defense Standards: As an ITAR-registered supplier and a member of IPC, our high-tech metal finishing solutions adhere to standards like MIL-DTL-26074 (for electroless nickel) and others so that the work we provide is suitable for critical aerospace and defense applications.

- Customization for Specific Needs: Since these sectors often require specialized finishes to meet unique performance characteristics, we have systems and the expertise to address any specific challenges from enhanced friction resistance to greater thermal stability for electronic components used in various electronic systems.

- Advanced Quality Control: We also have state-of-the-art testing and quality control protocols that enable us to thoroughly inspect our high-tech metal finishings for uniformity, adhesion strength, and overall performance which minimizes risks related to defects or failures in critical applications.

High-Tech Plating For Advanced Electronics in Automotive Parts

The automotive industry is experiencing a rapid shift toward advanced technologies like Autonomous Driving Assistance Systems (ADAS) and EVs, which rely heavily on high-performance electronics. ADAS features like collision detection and lane-keeping assist, depend on sensors and electronics that must function reliably in harsh environments.

Similarly, EVs require advanced powertrains, battery management systems, and thermal management solutions to maintain optimal performance. Both technologies present challenges like exposure to moisture, heat, and vibrations, demanding high-tech metal finishing solutions that provide exceptional durability and reliability for their components.

AFI’s plating solutions address these challenges. Finishes like electroless nickel and gold provide superior corrosion resistance, ensuring that automotive components remain functional and effective over time. The heat resistant properties of nickel and copper plating help with managing the thermal demands of EV powertrains and battery systems, while also improving the electrical conductivity of key components.

Other plating techniques we offer like ENIG plating, contribute to the miniaturization and precision of automotive electronics. These high-tech metal finishing solutions improve the wear resistance of connections, which makes the ADAS sensors and EV power control systems last longer.

Plating In the Telecommunications Industry

Many telecommunications components in high-speed networks and data centers require reliable plating. High-frequency connectors, circuit boards, and other electronic components for instance require plating to maintain low electrical resistance, reduce signal loss, and protect against oxidation.

Some Important High-Tech Plating Finishes Used in Telecommunications

- Gold plating, often used for connectors, minimizes contact resistance and improves conductivity in high-speed applications, ensuring that signals are transmitted with minimal interference.

- Copper plating is also used in our high-tech metal finishing processes to improve the conductivity of PCB traces and vias which optimizes the thermal management in densely packed data center systems.

At AFI, we meet these requirements by offering precision electroplating services that improve component performance in high-speed, high-reliability environments.

From our gold and nickel electroless platings that provide consistent, uniform coating for durability and corrosion resistance to nickel plating that we use to build up thickness and provide a base layer for subsequent gold coatings which ensure that connectors in high-frequency networks maintain optimal electrical contact for a long time, our high-tech metal finishing solutions meet the strict industry standards such as those required by telecom OEMs and data center infrastructure developers that need precise tolerances and performance under varying environmental conditions.