Rugged PCB Manufacturing & ITAR Registration

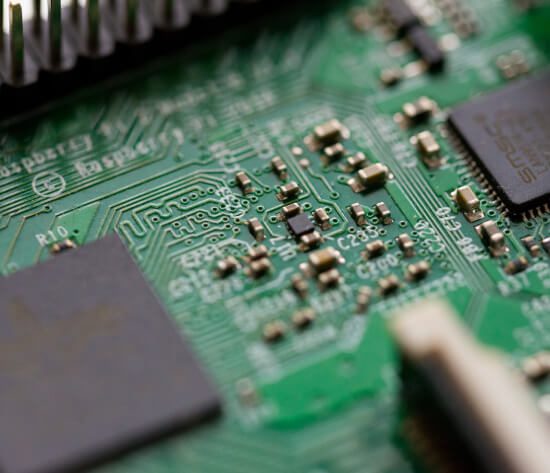

PCB manufacturers for military applications know that these electronic devices often endure conditions such as extreme environments, temperature fluctuations, and exposure to corrosive elements. Given these demanding circumstances, the electronic components must rely on high-quality plating that meets military-grade specifications to ensure their reliability and performance.

Military plating standards are primarily implemented by the Department of Defense to address factors like conductivity, insulation, hardness, ruggedness, chemical resistance, oxygen deprivation, while adhering to ITAR PCB compliance.

As a registered service provider under the International Traffic in Arms Regulations (ITAR), we meticulously adhere to the regulations governing the manufacture, export, and temporary import of defense articles. Additionally, we strictly comply with the rules surrounding the provision of defense services and brokering activities associated with items like military-grade PCBs and others listed on the United States Munitions List (USML).

These regulations undergo regular updates and revisions to align with advancements in technology, as well as changes in U.S. national security and foreign policy interests.

Military PCB Plating Services Offered by Alternate Finishing, Inc.

- Advanced PCB metal-plating for next-gen military and aerospace electronics

- High-reliability metal finishing for advanced military circuit boards and other defense electronics

- Custom metal finishing services for mission-critical electronics

- Innovative surface treatments for high-performance military PCBs

- Ultra-reliable metal finishing for military and aerospace applications

Features of Military and Defense PCBs

Military circuit boards are manufactured with unique specifications and features that set them apart from commercial-grade PCBs. Here are some of those features.

Mil-Spec Materials

The PCBs are constructed using specialized materials designed for harsh climates. These include high-performance laminates and substrates that offer superior thermal stability, mechanical strength, resistance to chemicals, moisture, and radiation. The common materials used in these PCBs include:

- High-Density Interconnect Materials: These provide higher circuit density and are ideal for compact, high-performance military grade electronic components.

- Polyimide and PTFE: These materials offer excellent thermal stability and resistance to high-frequency signals, often necessary for aerospace and radar applications.

- Ceramic-Based PCBs: These substrates are used in high-temperature applications due to their exceptional heat resistance and low thermal expansion.

Enhanced Plating and Coatings

Military PCBs also require advanced plating surfaces coatings to improve performance, ensure durability, and meet stringent standards. The most common plating techniques for these PCBs are gold plating, nickel plating, silver plating, and tin/lead plating.

ITAR Compliance and Regulatory Standards

Military circuit boards must adhere to a range of regulatory standards to ensure they meet the needs of defense and aerospace industries. Some of those regulations include:

- ITAR: This stands for International Traffic in Arms Regulation. ITAR governs the manufacturing, export, and import of defense-related technologies. Military PCBs must comply with ITAR’s regulations to ensure that they are not inadvertently diverted by unauthorized foreign entities.

- MIL-PRF-31032: This specification outlines the requirements for the performance, qualification, and testing of military-grade PCBs.

- MIL-STD-275: A standard for PCB fabrication that ensures the circuit boards meet the ruggedness and reliability requirements of military applications.

Mechanical and Thermal Properties

These PCBs must be able to endure extreme physical and environmental conditions, which require better mechanical properties and thermal management capabilities. Specific features that contribute to these properties include:

- Vibration resistance since they are always subjected to intense vibrations from military vehicles and missiles. Military PCBs must therefore be designed to resist fatigue, cracking, delamination and other effects.

- Shock resistance is also important for sudden impacts like explosive environments.

- Thermal management since heat dissipation in high-power military applications is so important. Military PCBs can have thermal vias, heat sinks, and ceramic substrates to manage high temperatures and prevent thermal damage.

Signal Integrity and High- Frequency Performance

Military circuit boards also need to maintain high-frequency performance and signal integrity for mission-critical applications like radar and communication systems. Features like impedance control to prevent signal loss and the use of low-loss materials like PTFE to reduce attenuation are among some of the many elements that ensure minimal signal degradation and reliable operation in demanding environments.

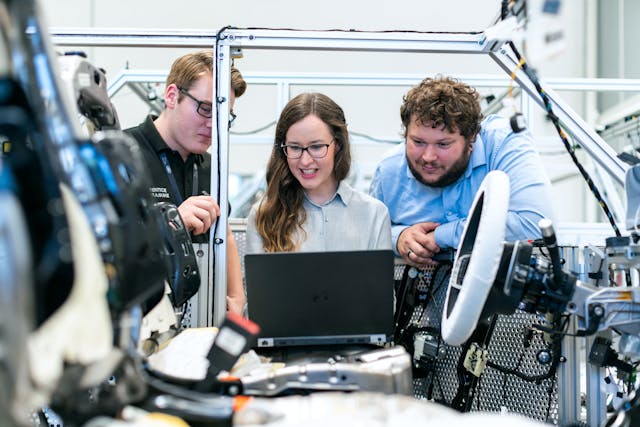

Work With Us

Whether you need leading-edge electroless nickel plating for defense PCBs, enhanced reliability through military-grade PCB metal finishing, advanced metal finishing for high-performance military electronics, or any other of the services we mentioned above, AFI is ready to work with you.

If you are located in the United States or Canada and require fast and reliable mil-spec plating services, call us for a free quote.