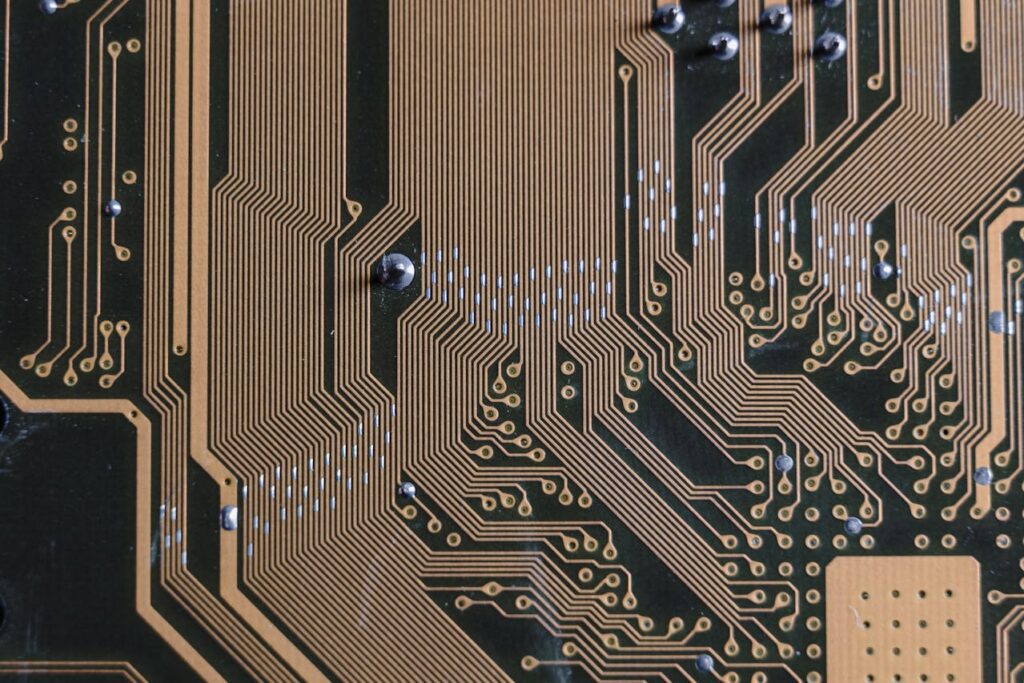

What is Circuit Board Plating?

Circuit board plating is a specialized process in electronics manufacturing where a thin metal layer is deposited onto a printed circuit board (PCB) or an electronic component. This surface finishing helps PCBs perform effectively for a long time but it also improves some desirable characteristics of these components such as having better conductivity, preventing corrosion, and improving solderability.

With the increasing complexity and miniaturization of electronic devices, the plating process also preserves the reliability of the end products and that is why industries from aerospace to consumer electronics rely on it to maintain high-quality performance in their applications.

There are several materials used in the plating process. Different plating materials like gold, silver, nickel, tin, and others are used. All of them have unique advantages and these characteristics influence the choice of choosing one over another

Benefits of Circuit Board Plating and the Metal Finishing Process

PCB plating offers numerous advantages that improve the quality and longevity of electronic components:

- Corrosion Resistance: The surface finishing process protects PCBs and electronic components from oxidation and environmental degradation, ensuring longer lifespans

- Improved Conductivity: Enhances electrical performance by reducing resistance and signal loss, which is crucial for high-speed applications.

- Enhanced Solderability: Ensures a reliable connection between PCB components and solder joints, preventing defects like cold joints.

- Wear Resistance: The plating processes strengthen connectors, switches, and high-use electronic components, increasing their durability.

- Thermal and Mechanical Stability: Certain plating materials, such as nickel, provide stability under high-temperature conditions, preventing degradation over time.

PCB Plating Processes

Steps

1

Quotation For Surface Finishing PCBs and Electronic Components

Our plating process at Alternate Finishing, Inc. begins with reviewing your requirements to understand the size and shape of the items to be worked on, the finish type, and the tolerances.

The price is calculated based on factors like materials, complexity, layer count, type of finish, and lead time. Some clients may have specific requests for expedited processing or custom finishes.

Steps

2

Order Preparation

Once your order is received, a detailed job tracking record is created to organize and guide the operators through the processing steps. This job tracking information provides all the necessary details for handling the parts according to your specifications, ensuring that every step of the plating process aligns with your original requirements.

Steps

3

Preparation

The PCB panels or parts are cleaned and prepared to remove contaminants and oxidation that could interfere with adhesion during the metal finishing process. Any areas that are not to be plated can be masked at this time as well.

The items will next be put on fixtures or racks to facilitate processing more than one at a time.

Steps

4

Coating Application

Depending on the final required surface finish for the PCBs or other components, the parts are processed through a series of chemical solutions with rinses between them to deposit the metal layers requested by our customer.

At this point in the plating process, the parts are rinsed in deionized water and dried.

Steps

5

Testing and Inspection

Finishes are checked for uniformity, thickness, and adhesion to ensure consistent results and adherence to the requirements.

Steps

6

Final Inspection and Packaging

Items are checked for cleanliness as they are being packaged. Parts are individually packaged, often with anti-static and moisture-resistant materials to prevent damage during shipping.

Steps

7

Documentation and Labeling

Packaging for shipment with the necessary documentation, such as quality certifications and any handling instructions is the next step

Final Step

Shipping or Pickup

The final step in our plating process is delivery: either through shipping or pick up. The logistics are tailored to your requirements for speed and destination

Detailed Examples and Applications of Circuit Board Plating

As we stated earlier, each material has its unique advantages and challenges. The choice of plating material for the surface finish of PCBs, therefore, affects the performance, durability, and functionality of the device. Here is an overview explaining how some industries rely on PCB plating technologies.

Aerospace and Defense

PCBs for aerospace and defense industries require the capability to withstand extreme environmental stresses like radiation and wide temperature fluctuations. This is why the most common plating processes used here are those that provide great resistance to corrosion and wear while maintaining reliable conductivity and preventing signal degradation over time.

The most common techniques that achieve a perfect balance of these characteristics and hence are used commonly here are electroless nickel immersion gold (ENIG), hard gold plating, and electrolytic nickel and gold plating.

Medical Devices

Unlike the aerospace and other industries, biocompatibility is just as important here as high conductivity and corrosion resistance are. These plating characteristics are necessary for medical-grade PCBs to function effectively within diagnostic and implantable devices.

Due to its inert nature and low contact resistance, gold plating is the process that is widely used for biosensors, ECG electrodes, and pacemaker circuits. Other highly used PCB surface finishing techniques are silver plating due to its high conductivity that makes it ideal for medical imaging and diagnostic equipment as Palladium-Nickel plating that improves the durability of implantable electronics by preventing material degradation due to bodily fluids.

Automotive and Electric Vehicles

Here, the PCBs are required to endure harsh operating conditions too such as exposure to chemicals, moisture, and varying temperatures.

Therefore, materials and techniques that are resistant to corrosion and wear are valuable here. This is why processes such as nickel-tin plating and immersion tin, for its environmentally friendly characteristics, are used.

Telecommunications

The demand for high-speed data transmission necessitates precision plating methods that ensure minimal signal and maximum durability.

For example, gold plating is commonly used in this industry. It is applied to connectors and edge contacts in fiber optic networking equipment to maintain low resistance over extended usage.

Copper-nickel plating also improves the thermal conductivity in high-performance servers which reduces the risk of overheating.

ENIG is also used and it is a preferred PCB surface finishing process for high-frequency PCBs and used in 5G infrastructure and cloud computing applications.

A Summary of Key Insights

- PCB plating processes significantly enhance the durability, conductivity, and corrosion resistance of electronic components.

- Various plating methods cater to different application needs.

- Material selection is important—gold offers superior conductivity and corrosion resistance, nickel provides a robust diffusion barrier, and tin serves as a cost-effective solderable surface

- Industries depend on reliable plating techniques to maintain proper functionality.

Work With Us

At Alternate Finishing, Inc., we serve customers across the USA and Canada. Our services are reliable with quick turnarounds on jobs. If you are ready for precision surface finishing of PCBs or other components, contact us today to discuss your requirements, and get a free quote.